Views: 0 Author: Site Editor Publish Time: 2025-10-13 Origin: Site

You might expect automation to always lower your labor costs, but that is not always the case with a robotic veneer layer stacker. Many factors shape the outcome, including how you run your operation. For example:

You may reduce headcount, especially when labor is hard to find.

Scheduling can become simpler if you struggle with workforce availability.

Production rates may increase, letting you run more shifts with fewer issues.

Robots often take over repetitive tasks, lowering injury risks and letting people focus on quality.

Automated stacking often improves consistency and overall stack quality.

You see the biggest labor cost savings when you run high-volume operations. Robotic veneer layer stackers work best in environments where you process large amounts of material every day. These machines keep up with fast-paced production lines and rarely slow down. You can rely on them to handle stacks quickly and consistently.

Here is a table that shows how automation improves your operation:

Benefit | Description |

|---|---|

Improve production efficiency | Automation completes veneer collection and sorting, enhancing production efficiency and reducing costs. |

Ensure the quality of veneers | Automated stacking prevents damage, maintaining veneer quality through careful handling. |

Reducing labor intensity | Less manual operation decreases worker labor intensity and enhances workplace safety. |

Improve automation degree | Integration with other equipment boosts overall production automation and intelligence. |

When you automate stacking, you need fewer workers for manual tasks. You can assign your team to other jobs that require skill or attention. You also lower the risk of injuries from repetitive lifting and moving.

Robotic stackers excel at repetitive tasks. You often see workers get tired or lose focus when they repeat the same motion for hours. Automation solves this problem. Robots do not get tired or distracted. You get consistent results every time.

Tip: Automated stacking prevents damage to veneers and keeps quality high. You avoid costly mistakes and rework.

You can reduce the number of manual laborers needed for stacking. Your team can focus on quality control or machine supervision. You also improve workplace safety because robots handle the heavy lifting.

Labor shortages affect many woodworking plants. You may struggle to find skilled workers for stacking jobs. Robotic veneer layer stackers help you solve this problem.

"If you have job openings you can’t fill, you’ve got to call the robot integrators. The labor shortage is the key."

Up to 82% of U.S.-based manufacturers face a significant shortage in skilled workers.

You can keep your production running even when you cannot hire enough people. Robots fill the gaps and keep your operation efficient. You also avoid delays and downtime caused by staff shortages.

You face a significant upfront cost when you choose a robotic veneer layer stacker. The price includes the machine itself, installation, and setup. You may need to upgrade your facility to support the new equipment. Some companies spend more than they expect because they overlook hidden costs like electrical work or safety barriers.

You should compare the initial investment to your current labor expenses. If you run a high-volume operation, the robot may pay for itself quickly. For smaller shops, the payback period can stretch longer. You need to calculate how many hours your team spends stacking veneers and how much you pay in wages. This helps you decide if automation makes sense for your business.

Tip: Always ask for a detailed quote before you commit. This helps you avoid surprises and plan your budget.

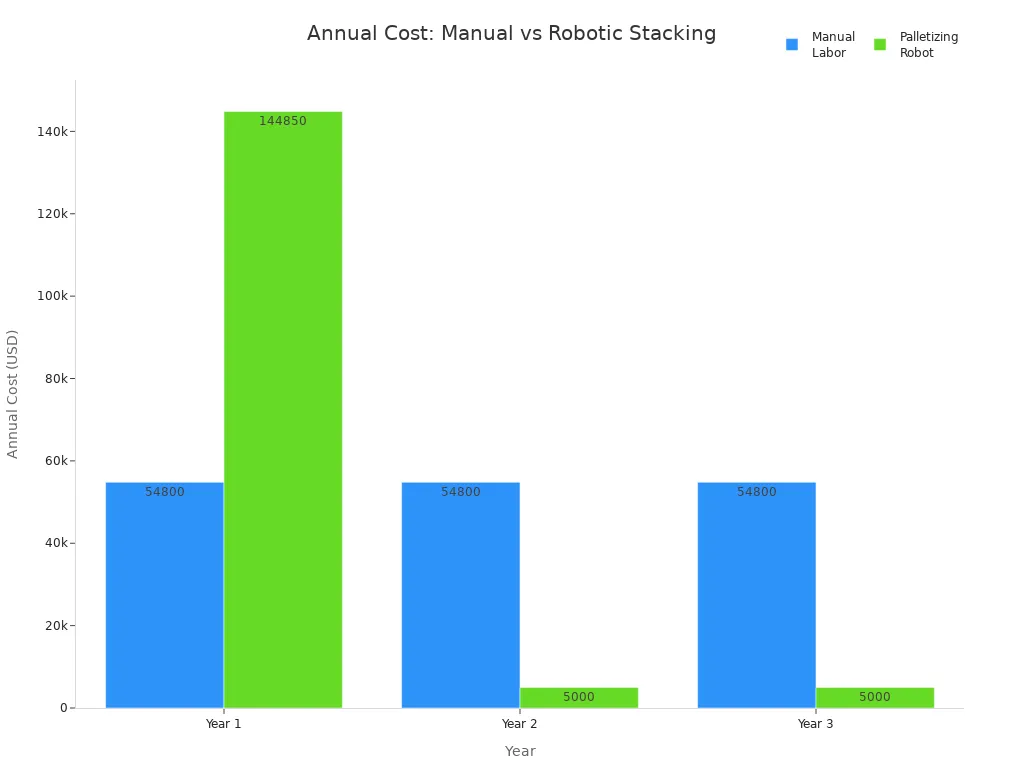

Robotic stackers need regular maintenance to keep running smoothly. You must budget for parts, service, and occasional repairs. These costs are lower than ongoing labor expenses over time. The following table shows how maintenance costs for a palletizing robot compare to manual labor over three years:

Expense | Manual Labor (1 worker per shift) | Palletizing Robot |

|---|---|---|

Year 1 | $54,800 | $139,850 + $5,000 (maintenance) |

Year 2 | $54,800 | $5,000 (maintenance) |

Year 3 | $54,800 | $5,000 (maintenance) |

Total Cost Over 3 Years | $164,400 | $149,850 |

You see that the robot pays for itself within two to three years. After the first year, your costs drop sharply. You spend much less on maintenance than you would on wages for manual stacking.

You may face challenges when you add a robotic stacker to your production line. The machine must work with your existing equipment. Sometimes you need to change your workflow or adjust your layout. You may need help from engineers or automation experts.

You should plan for a learning curve. Your team must learn how to operate and troubleshoot the robot. Training takes time and resources. You may experience some downtime during the transition. Careful planning helps you avoid delays and keeps your operation running smoothly.

Note: Good communication with your supplier makes integration easier. Ask for support and training to help your team succeed.

When you bring a robotic veneer layer stacker into your plant, you must prepare your team for new ways of working. Training becomes a key factor in your success with automation. You cannot expect your staff to operate advanced machinery without proper instruction.

Why Training Matters

You need skilled operators to run and monitor the robotic stacker.

Maintenance staff must learn how to troubleshoot and fix issues.

Supervisors should understand the basics of programming and safety protocols.

If your team lacks these skills, you may face downtime or costly mistakes. Well-trained employees help you get the most from your investment.

Tip: Schedule training sessions before the robot arrives. Early preparation reduces confusion and keeps your production on track.

What Training Involves

Training covers several areas:

Basic Operation: Your staff learns how to start, stop, and monitor the stacker. They practice loading materials and responding to alerts.

Safety Procedures: You must teach everyone about emergency stops, safety barriers, and lockout/tagout rules. Safety training prevents accidents.

Routine Maintenance: Operators and technicians learn how to clean, inspect, and replace parts. Regular care keeps the robot running smoothly.

Troubleshooting: Your team practices diagnosing common problems. Quick fixes reduce downtime and keep production moving.

Software Skills: Some stackers use touchscreens or computer interfaces. Staff must learn to adjust settings and read data.

Training Methods

You can use different methods to train your team:

On-site instruction: A technician visits your plant and teaches your staff in person.

Online courses: Many suppliers offer video tutorials and digital manuals.

Hands-on practice: Staff members learn best when they work directly with the machine.

A mix of these methods works well. You should choose the approach that fits your team’s learning style.

Training Costs and Time

Training adds to your initial investment. You may need to pay for instructor fees, travel, or online courses. Training can take several days or even weeks, depending on your team’s experience.

Training Type | Estimated Time | Typical Cost Range |

|---|---|---|

On-site instruction | 2-5 days | $2,000-$5,000 |

Online courses | 1-3 days | $500-$1,500 |

Hands-on practice | Ongoing | Included/Varies |

You should plan for this time and cost. Well-trained staff help you avoid bigger expenses later.

Note: Some suppliers include training in the purchase price. Always ask what is covered before you buy.

Long-Term Benefits

Investing in training pays off. Your team works more confidently and safely. You reduce errors and downtime. Over time, you see better results from your robotic veneer layer stacker.

You may not see labor cost savings if your operation runs at a low production volume. Robotic veneer layer stackers come with high fixed costs. You pay for commissioning and programming the equipment, no matter how much you produce. These expenses can make each unit more expensive when you process small batches.

You also face high non-productive time during startup and changeovers. Workers spend more time setting up the machine than actually stacking veneers. This increases the average labor cost per unit. Small batches do not allow you to recover high mold expenses. You miss out on economies of scale in material procurement, which raises your unit costs.

Here is a table that shows why low production volume can hurt your savings:

Factor | Explanation |

|---|---|

Commissioning and programming equipment | High fixed costs inflate unit costs in low-volume production. |

Inadequate amortization of unit labor | Startup and changeover time increases average unit labor costs. |

Disadvantages in material procurement | Small orders prevent bulk discounts, raising material costs. |

Mismatch with economic batch size | Small batches do not recover high mold expenses, increasing costs. |

Note: If your shop runs small batches or custom orders, you may not benefit from automation as much as larger facilities do.

You may need to produce custom veneer stacks for special projects or clients. Robotic stackers work best with standardized tasks. If you change your product specifications often, you spend more time reprogramming the robot. This leads to downtime and extra labor costs.

Manual stacking allows for quick adjustments. Workers can respond to unique requests without stopping production. Robots need new instructions and sometimes new tooling for each change. You may find that automation slows you down when you handle many custom jobs.

Tip: Evaluate how often you need to customize your stacks before investing in a robotic solution.

Robotic veneer layer stackers require ongoing technical support. You may need help from engineers or automation specialists when problems arise. Support contracts, spare parts, and emergency repairs add to your operating costs.

If your team lacks experience with robotics, you may rely on outside experts more often. This increases your expenses and can lead to longer downtimes. You should consider these costs when calculating your potential savings.

You pay for software updates and troubleshooting.

You may need to upgrade hardware as technology changes.

Emergency repairs can disrupt your schedule and budget.

Alert: Technical support costs can offset labor savings, especially if your operation is small or lacks in-house expertise.

You want every stack of veneer to look the same and meet your standards. A robotic veneer layer stacker gives you consistency in your production. Automation removes the risk of human error and fatigue. You get consistent results with every cycle. The robot uses smart sensors and AI-powered controls to adjust for thickness and placement. This technology keeps your veneer stacks uniform and reduces waste. Automated solutions handle delicate materials with care, so you see fewer damaged pieces. You can trust the robotic veneer layer stacker to deliver reliable quality shift after shift.

Tip: If you need high-quality veneer stacks for demanding clients, automation helps you meet strict requirements every time.

You can boost your output with a robotic veneer layer stacker. Automation works faster than manual labor and does not slow down. Robots keep stacking at high speed, even during long shifts. You see a big difference in how many boxes you process each hour. The table below shows how robotic stacking compares to manual stacking:

Stacking Method | Output per Hour |

|---|---|

Robotic Stacking | Over 800 boxes/hour |

Manual Stacking | 350-400 boxes/hour |

Robotic systems maintain high speeds and consistent stacking patterns. You reduce errors and improve efficiency. Smart gripper design can more than double your throughput. Automation lets you run more shifts with fewer breaks. You can meet tight deadlines and handle large orders with ease. If you want to upgrade your operation, consider brands like Alva Machinery for advanced robotic veneer layer stacker options.

You protect your team when you use a robotic veneer layer stacker. Automation takes over the heavy lifting and repetitive motions that often cause injuries. You see fewer accidents and less strain on your workers. The introduction of industrial robots, including robotic veneer layer stackers, has been linked to a reduction in workplace injuries, especially in high-tech sectors. In 2022, nearly 3 million workplace accidents were recorded in the EU, showing that safety challenges remain. The effectiveness of robotic implementation in reducing injuries depends on your industry and how well you train your staff.

Robots handle dangerous tasks and keep people away from moving parts.

You lower the risk of back injuries and repetitive strain.

Automated solutions create a safer work environment for everyone.

Note: You should always provide safety training and follow best practices when you add automation to your plant.

You want your woodworking shop to run as smoothly as possible. Robotic veneer layer stackers help you speed up every step. When you use automation, you move materials faster and keep your production line moving. You do not have to wait for workers to finish stacking by hand. Machines handle the job quickly and do not need breaks. This change boosts your woodworking efficiency and lets you finish more projects in less time.

You can see the difference in your daily output. For example, a robotic stacker can process hundreds of veneer sheets per hour. Manual stacking often takes much longer. You save time on each order and can take on more work. If you want to see how much faster your shop can run, try tracking your production before and after adding automation.

Tip: Faster processing means you can meet tight deadlines and keep your customers happy.

Here is a simple comparison:

Method | Sheets Stacked per Hour | Downtime Needed |

|---|---|---|

Manual Stacking | 350-400 | Frequent |

Robotic Stacking | 800+ | Minimal |

You can see that robotic systems double your speed. This improvement helps you stay ahead in the woodworking industry.

You know that waste can hurt your profits in woodworking. Every damaged veneer sheet or misplaced stack costs you money. Robotic veneer layer stackers help you cut down on waste. These machines use sensors and smart controls to handle each sheet with care. You get fewer mistakes and less material loss.

When you improve woodworking efficiency, you also use your resources better. Robots stack veneers with precision, so you do not throw away as many sheets. You also avoid rework, which saves you time and effort. Less waste means you spend less on materials and increase your profit.

Note: Reducing waste is good for your business and the environment. You use fewer raw materials and create less trash.

If you want to upgrade your woodworking shop, consider advanced robotic solutions. Some brands, like Alva Machinery, offer machines designed for high woodworking efficiency and low waste.

Here are some ways robotic stackers reduce waste:

Sensors detect defects and remove bad sheets.

Precise stacking prevents damage during handling.

Consistent operation lowers the risk of human error.

You can see real savings when you track your waste before and after automation. Improved woodworking efficiency leads to better results for your shop.

You should start your cost-benefit analysis by looking at your specific needs. Every production line is different. You need to decide if a robotic veneer layer stacker fits your goals. In modern manufacturing, you often have several options. You can choose manual labor, partial automation, or full automation. You should list all possible projects and decide who will benefit most from each choice. Think about your team, your customers, and your business.

Here is a simple table that shows the steps you should follow:

Step | Description |

|---|---|

1 | Specify the set of alternatives projects. |

2 | Decide who will be the key stakeholder for the benefits and costs. |

3 | List impacts and determine ways to measure them. |

4 | Predict impacts quantitatively over the life of the project. |

5 | Monetize every impact. |

6 | Discount benefits and costs to obtain present values. |

7 | Calculate the net present value of each alternative. |

8 | Perform sensitivity analysis. |

9 | Make a recommendation. |

You should measure how each option affects your output, safety, and quality assurance. You can use numbers to predict how much you will save or spend over time. This process helps you make smart decisions in modern manufacturing.

Tip: Always include your team in the decision-making process. Their experience on the production line can help you spot hidden costs or benefits.

You need to look beyond the price tag when you compare robotic veneer layer stackers to manual labor. The total cost of ownership includes everything you pay over the life of the machine. In modern manufacturing, you must consider initial investment, operational costs, and long-term savings.

Here is a table that compares robotic solutions and manual labor:

Cost Factor | Robotic Solutions | Manual Labor |

|---|---|---|

Initial Investment | Higher upfront costs | Lower initial costs |

Operational Costs | Maintenance, software updates, energy | Wages, benefits, training, breaks |

Long-Term Savings | Substantial savings from automation | Costs increase over time due to turnover |

Productivity | Operates continuously, reducing downtime | Limited by human capacity and breaks |

Human Error | Reduced with automation | Higher risk of errors |

You may pay more at first for a robotic stacker, but you often save money in the long run. Robots work without breaks and keep your production line moving. You see fewer mistakes and less waste. Manual labor costs can rise over time, especially if you have high turnover. In modern manufacturing, you need to think about how each choice affects your output and quality assurance.

Note: If you want to see real savings, track your costs and output for both manual and automated systems over several years.

You should not focus only on labor costs when you analyze robotic veneer layer stackers. Modern manufacturing brings many non-labor benefits. Automation improves quality assurance by making your output more consistent. Robots help you meet strict standards and reduce the risk of damaged products.

Here are some non-labor benefits you may notice:

Improved safety for your team

Higher output and faster production line speeds

Better quality assurance with fewer errors

Lower waste and more efficient use of materials

Easier compliance with industry standards

You can also boost your reputation with customers who value reliable output. If you want to upgrade your production line, consider brands like Alva Machinery. Their products support modern manufacturing and help you reach your goals.

Callout: Non-labor benefits can make a big difference in your business. You may see gains in safety, quality assurance, and customer satisfaction.

Many people believe that robotic veneer layer stackers always save money on labor. This is not always true. You need to look at your own operation before you expect big savings. Some companies find that hidden costs or low production volumes reduce the benefits of automation. Others discover that robots work best when they support, not replace, skilled workers.

Here is a table showing common misconceptions and the real story:

Misconception | Reality |

|---|---|

Robots always cut costs | Savings depend on your production volume, setup, and ongoing expenses. |

Automation replaces all workers | Workers and robots work best together. Robots handle repetitive tasks, while people solve problems. |

Labor costs disappear | Hidden labor costs and support needs can still affect your budget. |

Note: You should see robots as a tool to help your team, not as a magic solution for every problem.

You might overlook several hidden costs when you invest in robotic veneer layer stackers. These expenses can add up and affect your total savings. Always check for these extra costs before you make a decision:

Installation costs, such as building special work areas or adding backup power units.

Extra technology, like sensors and special robot grippers, that may be needed for your products.

Engineering and ongoing maintenance, which can change over time and may require expert help.

Variable costs, including labor for supervision, energy use, materials, and production supplies.

Tip: Make a checklist of all possible costs before you buy. This helps you avoid surprises and plan your budget better.

Switching to robotic veneer layer stackers changes how your team works. Some workers may worry about losing their jobs. Others may need new skills to work with the machines. You should help your team see robots as partners, not threats. When you combine the strengths of people and robots, you get the best results.

Train your staff early so they feel confident with new technology.

Explain how automation can make their jobs safer and less tiring.

Show that robots can handle hard or boring tasks, letting people focus on quality and problem-solving.

Callout: Workers and robots can work side by side. This approach helps you get the most from your investment and keeps your team strong.

If you want to explore advanced robotic veneer layer stackers, you can check out brands like Alva Machinery, which offer solutions designed for both efficiency and teamwork.

You can often reduce labor costs with a robotic veneer layer stacker, but you will not see savings every time. You must look at your operation’s needs, including production efficiency, precision, and performance. Precision matters for every stack, every time, especially when you want a high-quality finish and reliable surface finishing. You should measure performance over time and check if smart manufacturing fits your workflow. Take time to compare options and analyze costs. You can visit Alva Machinery for advanced solutions. Make sure you consider all benefits, not just labor, before you invest.

A robotic veneer layer stacker is a machine that stacks veneer sheets automatically. You use it to improve speed and consistency in your woodworking shop. This tool helps you handle veneer efficiently and reduces manual labor.

Automation keeps veneer quality high. You get uniform stacks because the robot uses sensors to place each veneer sheet accurately. This process lowers the risk of damage and helps you meet strict quality standards.

You can use robotic stackers for most veneer types. Some machines handle thin, delicate veneer sheets. Others work with thicker veneer. Always check the specifications before you choose a stacker for your veneer needs.

Yes, robotic stackers help you reduce veneer waste. Sensors detect defects and remove bad veneer sheets. Precise stacking prevents damage. You save money and protect your resources by using veneer more efficiently.

You need regular maintenance for your veneer stacker. Clean sensors and moving parts often. Replace worn components as needed. Scheduled service keeps your veneer stacker running smoothly and extends its life.

You train your staff with hands-on practice and online courses. Teach them how to load veneer, operate controls, and follow safety rules. Good training helps your team use the veneer stacker safely and efficiently.

Robotic veneer stackers may not suit every small shop. You should compare your veneer production volume and labor costs. If you run many veneer batches, automation can save money. For low-volume veneer work, manual stacking may cost less.

You can find advanced veneer stackers from brands like Alva Machinery. Their products support efficient veneer stacking and help you improve your woodworking operation. Visit Alva Machinery for more details.