Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

Choosing the right Gear Pressing Veneer Peeling Machine for your business in 2025 starts with understanding what you need. Look at your production goals, the types of wood you work with, and how much space you have in your workshop. Automation and efficiency can boost your output and improve product quality. Cost matters, but future-proofing helps your business grow.

The right veneer press can transform your workflow, making jobs faster and smoother. Check out the latest technology trends and pick a machine that's easy for your team to use.

When you start looking for a gear pressing veneer peeling machine, you need to think about your production needs. This means figuring out what kind of wood you use, how much you want to produce, and what your final product should look like. Let’s break down these factors so you can make the best choice for your business.

The type of wood you process makes a big difference. Some machines work better with hardwoods, while others handle softwoods or fast-growing species. You also need to check the diameter of the logs you plan to use. If you work with larger logs, you’ll need a machine that can handle them without slowing down your production. For example, spindleless veneer peeling machines are great for logs up to 600mm in diameter and work well with fast-growing woods. If you use premium woods or need consistent veneer sheets, a premium veneer peeling machine might be the right fit.

Tip: Always match your machine to the wood you use most often. This helps you avoid downtime and keeps your production running smoothly.

How much veneer do you need to produce each day? Your answer will guide you toward the right machine size and capacity. If you run a large operation, you’ll want a machine that can keep up with high production demands. Smaller workshops might need a compact model that fits their space and budget. A good rule is to pick a machine that can handle at least 80 to 90 percent of your daily workload. This keeps your machine working efficiently and reduces wear and tear.

If your machine is too small, it will struggle and break down more often.

If your machine is too big, you might waste energy and money.

Matching your machine’s horsepower and capacity to your job size means you get consistent performance and less downtime. You’ll also save on operational costs and keep your production line moving.

Your final product matters just as much as your raw materials. Think about the thickness, width, and quality of the veneer you want to produce. Different machines offer different features to help you meet your goals. Here’s a quick look at how machine types match up with product specifications:

Machine Type | Features | Applications |

|---|---|---|

Advanced technology for consistent veneer sheets, adjustable settings | Plywood, OSB, cardboard composites | |

8 Feet Veneer Peeling Machine | High temperature quenching for durability, accurate veneer width/thickness | High-quality veneer production |

Spindleless Veneer Peeling Machine | Designed for fast-growing wood species, max log diameter of 600mm | Core veneer production |

You want a machine that delivers the right thickness and width every time. Premium machines help you minimize waste and boost quality. If you need high-quality veneer for plywood or composites, look for machines with advanced settings. For core veneer production, spindleless models offer speed and efficiency.

If you’re not sure which machine fits your production needs, check out trusted brands like Alva Machinery. Their range of veneer peeling machines covers different wood types, log sizes, and production volumes. You can find more details at Alva Machinery’s product page.

When you start shopping for veneer machines, you’ll notice several types on the market. Each type has its own strengths and fits different business needs. Let’s look at the main types you’ll find in 2025.

You’ll see gear pressing veneer peeling machine models in many modern workshops. These machines use gears to control the peeling process. You get steady pressure and smooth operation. If you want consistent veneer thickness and high-quality sheets, this type stands out. Gear pressing veneer peeling machine options work well with a range of wood types. You can adjust settings for different log diameters. Many businesses choose this type for its reliability and easy maintenance. You also get better control over speed and output, which helps you meet tight deadlines.

Tip: Gear pressing veneer peeling machine models from trusted brands like Alva Machinery offer advanced features and solid construction. You can find machines that match your production needs and budget.

Hydraulic presses use fluid power to apply force. You get strong pressure and can handle tough woods. Vacuum presses use suction to hold veneer in place during pressing. These types work best for specialty jobs. If you need to press curved or irregular shapes, vacuum presses make the job easier. Hydraulic presses suit businesses that want flexibility and power. You can switch between different wood types and thicknesses without much hassle.

Here’s a quick comparison:

Machine Type | Best For | Key Benefit |

|---|---|---|

Hydraulic Press | Thick or tough veneer | High pressure, flexibility |

Vacuum Press | Curved or shaped veneer | Gentle handling, precision |

Multi-daylight presses let you process several veneer sheets at once. You stack sheets in layers and press them together. This type boosts your output and saves time. If you run a large operation, multi-daylight presses help you meet high-volume demands. You get uniform results and can handle big batches. Many factories use these presses for plywood and composite production.

Heavy-duty wood veneer clippers also play a key role in high-volume production. They offer efficiency, precision, and durability. You might pay more upfront, but you save money in the long run with fewer breakdowns and better results.

When you compare these types, think about your business goals. Gear pressing veneer peeling machine models give you control and consistency. Hydraulic and vacuum presses offer flexibility for special jobs. Multi-daylight presses and heavy-duty clippers help you scale up and meet big orders. If you want to explore more options, check out Alva Machinery’s product lineup for machines that fit every need.

Automation has changed the way you handle veneer production. In 2025, you see machines that almost run themselves. You can set up your gear pressing veneer peeling machine and let it do the hard work. Here are some of the latest advancements you’ll notice:

Spindleless technology now reduces wood waste by up to 20%. You get more veneer from every log.

Most new machines come with CNC controls and IoT integration. This means you can monitor veneer thickness in real time and make quick adjustments.

Servo-motor systems and AI-driven software help you set up jobs faster. You spend less time on trial and error and get fewer defects in your veneer sheets.

Tip: When you choose a machine with these features, you boost your productivity and cut down on waste. If you want to see what’s available, check out the latest models from Alva Machinery.

CNC integration is one of the most important features in modern veneer machines. It gives you control and precision that older machines just can’t match. With CNC, you can program exact settings for thickness, speed, and cutting. This means you get the same high-quality veneer every time.

Here’s a quick look at how CNC integration improves your results:

Feature | Benefit |

|---|---|

CNC PLC control systems | Keeps operation stable and veneer thickness uniform at high speeds |

Servo motors | Controls feeding and cutting for consistent veneer thickness |

Feedback loops | Adjusts speed and tool position for perfect cuts |

Frequency converters | Lets you change speed for different wood types |

Ball screws and linear guides | Makes positioning accurate and smooth |

Hydraulic knife systems | Allows quick knife changes and precise gap adjustments |

Integrated automation | Keeps veneer thickness within ±0.1mm tolerance |

Production speed | Runs up to 150 meters per minute without losing quality |

Industrial-grade components | Delivers smooth veneer surfaces and less waste |

You don’t have to worry about uneven sheets or wasted material. CNC integration helps you get the most out of every log.

Efficiency is the key to running a successful veneer operation. You want a machine that works fast, uses less wood, and keeps quality high. When you look at gear pressing veneer peeling machines, pay attention to these important metrics:

Metric | Description | Importance |

|---|---|---|

Peeling Speed | How fast the machine peels veneer (m/min) | Higher speeds mean more veneer in less time |

Peeling Precision | How close the machine stays to your set thickness | High precision gives you uniform, usable veneer |

Cutting Thickness | Range of veneer thickness you can produce | More options for different products |

Processing Diameter | Size of logs the machine can handle | Bigger range means more flexibility |

Core Diameter | How small the leftover log core can be | Smaller cores mean less waste and more veneer |

When you choose a machine with strong efficiency features, you save money and time. You also get more usable veneer from every log. Alva Machinery offers machines that hit all these marks, so you can keep your business running smoothly.

When you choose a gear pressing veneer peeling machine, you want something your team can operate without stress. Ease of use matters more than you might think. If your machine feels complicated, you waste time on training and troubleshooting. A user-friendly design helps you get started fast and keeps your workflow smooth.

Let’s look at what makes a veneer peeling machine easy to use:

Intuitive Controls: Modern machines come with touchscreens and clear buttons. You don’t need to memorize complex steps. You just tap, set, and go.

Simple Setup: You can switch between wood types or adjust thickness with a few quick changes. No need for special tools or long manuals.

Clear Displays: Digital screens show you real-time data. You see speed, thickness, and output at a glance. This helps you catch problems early.

Accessible Maintenance: You reach key parts without crawling under the machine. Routine cleaning and checks take minutes, not hours.

Tip: If you want less downtime, pick a machine with easy access panels and self-diagnosis features. These save you headaches when something goes wrong.

Here’s a table that shows how ease of use can impact your daily operations:

Feature | Benefit | Impact on Workflow |

|---|---|---|

Touchscreen Controls | Fast setup, easy adjustments | Less training time |

Quick-Change Settings | Switch jobs in minutes | More flexibility |

Self-Diagnosis Alerts | Automatic error detection | Fewer breakdowns |

Tool-Free Maintenance | No special tools needed | Faster repairs |

You don’t want your team stuck with confusing instructions or hard-to-reach parts. Machines with ergonomic layouts and smart automation let you focus on production, not troubleshooting. If you have new staff, they can learn the basics in a day. Experienced operators appreciate features that cut down on repetitive tasks.

Many top brands now design machines with operators in mind. For example, Alva Machinery offers veneer peeling machines with user-friendly interfaces and easy maintenance. You can check out their latest models at Alva Machinery’s product page.

If you want to boost productivity and keep your team happy, choose a machine that puts ease of use first. You’ll spend less time fixing problems and more time making quality veneer. That’s a win for your business every day.

Speed matters when you want to keep your production line moving. If you use a spindle peeling machine, you can process logs quickly and keep up with high demand. Many modern machines finish a cycle in less than three minutes. This means you get more veneer sheets in less time. You save energy and reduce labor costs. Fast machines help you meet tight deadlines and handle big orders without stress.

Here’s a quick look at industry benchmarks for speed:

Metric | Benchmark Value |

|---|---|

Cycle Time | ≤3 minutes for short-cycle presses |

If you run a busy workshop, you need a spindle-less peeling machine that can keep up. These machines work fast and don’t slow down, even with larger logs. You get steady output and fewer bottlenecks. When you choose a machine with high-speed features, you boost your daily production and keep your customers happy.

Tip: Fast machines help you stay ahead of competitors. If you want to see what’s available, check out the latest spindle peeling machine models from trusted brands like Alva Machinery.

Precision is the secret to making high-quality veneer. You want every sheet to have the same thickness and smooth surface. A spindle-less peeling machine gives you tight control over peel thickness. Many machines now use advanced technology to keep temperature consistent within ±2°C. This helps you avoid defects and waste.

Take a look at how precision control works in veneer production:

Feature | Description |

|---|---|

Precision Control | Extremely small tolerances for peel thickness |

Temperature Consistency | ±2°C |

Production Efficiency | High-speed and efficient peeling |

If you use a spindle peeling machine with CNC controls, you can set exact measurements for each job. You get uniform sheets every time. This means less scrap and better product quality. Spindle-less peeling machine models also help you switch between wood types without losing accuracy. You spend less time adjusting settings and more time making perfect veneer.

Note: Machines with precision control help you reduce waste and improve your bottom line. You get more usable veneer from every log.

Reliability keeps your workshop running day after day. You want a spindle-less peeling machine that works without constant repairs. High-quality machines use strong materials for key parts. Manufacturers test each spindle peeling machine to make sure it meets strict standards. You get high wear resistance and fewer breakdowns.

Here are some features that boost reliability:

High-quality materials used for key components

Rigorous quality testing and precision machining

Extremely high wear resistance and reliability

If you choose a spindle peeling machine from a trusted brand, you get peace of mind. Your machine lasts longer and needs less maintenance. Spindle-less peeling machine models also offer strong reliability, even in busy workshops. You spend less on repairs and keep your production line moving.

Tip: Reliable machines help you avoid costly downtime. For long-lasting performance, look for spindle peeling machine models from brands like Alva Machinery.

Keeping your gear pressing veneer peeling machine in top shape makes a huge difference in your daily operations. You want a machine that doesn’t slow you down with constant repairs or complicated upkeep. Regular maintenance helps you avoid costly breakdowns and keeps your production line running smoothly.

Let’s look at what you should consider when it comes to maintenance:

Routine Checks: Inspect your machine every day. Look for loose bolts, worn gears, or any signs of leaks. Catching small issues early saves you from bigger problems later.

Cleaning: Dust and wood chips build up fast. Clean the machine after each shift. This keeps moving parts working well and prevents jams.

Lubrication: Apply oil to gears and bearings as recommended. Smooth movement means less wear and tear.

Blade Care: Sharpen or replace blades regularly. Dull blades slow down production and lower veneer quality.

Software Updates: If your machine uses CNC controls, check for updates. New software can fix bugs and improve performance.

Tip: Set up a simple maintenance schedule. Use a checklist so your team knows what to do each day, week, and month.

Here’s a table to help you organize your maintenance tasks:

Task | Frequency | Why It Matters |

|---|---|---|

Visual Inspection | Daily | Prevents sudden breakdowns |

Cleaning | After shifts | Keeps machine running smoothly |

Lubrication | Weekly | Reduces friction and wear |

Blade Sharpening | Monthly | Maintains veneer quality |

Software Update | As needed | Ensures top performance |

You don’t want to spend hours fixing problems that could have been avoided. Machines with easy-access panels and tool-free maintenance features make your life easier. If you choose a model with self-diagnosis alerts, you get notified before something goes wrong.

When you pick a gear pressing veneer peeling machine, ask about after-sales support and warranty. Reliable brands like Alva Machinery offer strong customer service and clear maintenance guides. You get peace of mind knowing help is just a call away.

️ Pro Tip: Train your team on basic troubleshooting. If everyone knows how to spot and fix minor issues, you reduce downtime and keep production moving.

A well-maintained machine lasts longer and delivers better results. You save money, avoid stress, and keep your business growing. Make maintenance a priority, and your gear pressing veneer peeling machine will reward you with years of reliable service.

You want your workshop to run smoothly, so the footprint of your gear pressing veneer peeling machine matters. Start with a solid workbench. This gives you a stable base for all your woodworking tasks. If you have a small space, pick a workbench that is at least 5 feet long and 18 to 24 inches deep. This size fits most veneer machines and lets you move around easily. Use your wall space for tool storage. Shallow shelves and pegboards keep tools close without taking up floor space.

Place your machine where you can reach it from both sides.

Leave enough room for loading logs and removing finished veneer.

Keep walkways clear to avoid accidents and speed up your workflow.

Tip: A well-planned layout saves time and helps your team work safely. If you need compact machines, Alva Machinery offers models designed for smaller workshops. Check their product page for options that fit tight spaces.

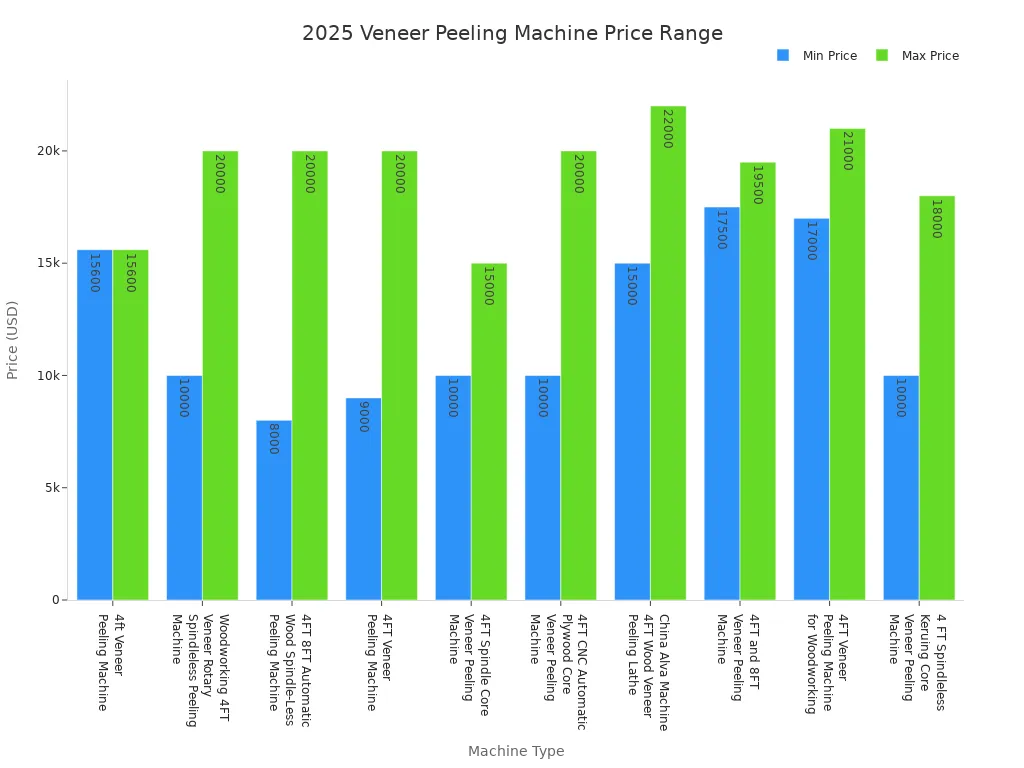

Setting your budget is a big step when choosing a veneer peeling machine. Prices vary by type and features. You want to get the best value without overspending. Here’s a quick look at the typical price range for machines in 2025:

Machine Type | Price Range (USD) |

|---|---|

4ft Veneer Peeling Machine | 15,600 |

Woodworking 4FT Veneer Rotary Spindleless Peeling Machine | 10,000 - 20,000 |

4FT 8FT Automatic Wood Spindle-Less Peeling Machine | 8,000 - 20,000 |

4FT Veneer Peeling Machine | 9,000 - 20,000 |

4FT Spindle Core Veneer Peeling Machine | 10,000 - 15,000 |

4FT CNC Automatic Plywood Core Veneer Peeling Machine | 10,000 - 20,000 |

China Alva Machine 4FT Wood Veneer Peeling Lathe | 15,000 - 22,000 |

4FT and 8FT Veneer Peeling Machine | 17,500 - 19,500 |

4FT Veneer Peeling Machine for Woodworking | 17,000 - 21,000 |

4 FT Spindleless Keruing Core Veneer Peeling Machine | 10,000 - 18,000 |

You see that most machines fall between $10,000 and $22,000. Think about your production needs before you set your budget. If you want advanced features or higher output, plan for the upper end of the range. Alva Machinery has models for every budget, so you can find one that matches your goals.

Reliable support makes your investment worthwhile. You want a brand that stands behind its machines and helps you solve problems fast. Good support means less downtime and fewer headaches.

Here’s a table showing how top brands handle warranty and support:

Brand/Model | Warranty | After-sales Support |

|---|---|---|

Guoyu Machinery | 1 year | Comprehensive services with 7 technicians available 365 days a year |

Mstar | 12 months | Door to Door Service |

Yuequn | 3 years | Video Technical Support, Online Support |

Guoyu Machinery is known for quality and stable performance.

Mstar gives you door-to-door service for 12 months.

Yuequn offers a 3-year warranty and video technical support.

Alva Machinery also provides strong support for their machines. You get installation videos, online help, and technical exchange. This kind of support keeps your machine running and your team confident.

Note: Always check warranty terms and support options before you buy. A good warranty lowers your long-term costs and gives you peace of mind.

If you want more details, visit Alva Machinery’s product page to see their support and warranty options.

When you invest in a gear pressing veneer peeling machine, you want peace of mind. A solid warranty gives you that. You know your machine will keep working, and you have support if something goes wrong. Most top brands offer warranties that cover parts and labor for a set period. You should always check the details before you buy.

Here’s what you need to look for in a warranty:

Coverage Period: How long does the warranty last? Some brands offer one year, while others go up to three years.

Parts and Labor: Does the warranty cover both? You want protection for major components and the cost of repairs.

Service Response: How fast can you get help? Quick service means less downtime.

Exclusions: What isn’t covered? Read the fine print so you know what to expect.

Tip: A longer warranty often means the manufacturer trusts their product. You get more value and fewer worries.

Let’s compare some warranty options from leading brands:

Brand | Warranty Length | Coverage Details | Service Type |

|---|---|---|---|

Alva Machinery | 1-3 years | Parts, labor, technical support | Online & onsite help |

Guoyu Machinery | 1 year | Full service, 7 techs available | 365-day support |

Yuequn | 3 years | Video and online support | Fast response |

Alva Machinery stands out with flexible warranty terms and strong support. You can find machines with up to three years of coverage. Their team helps you with installation, repairs, and technical questions. If you want to see their latest models and warranty details, visit Alva Machinery’s product page.

A good warranty protects your investment. You avoid surprise costs and keep your production running. Always ask about warranty terms before you make a decision.

Even the best veneer peeling machines need attention sometimes. You want to fix problems fast and keep your workshop moving. Troubleshooting helps you spot issues early and solve them before they get worse.

Here are some common problems and quick fixes:

Machine won’t start: Check the power supply and safety switches. Make sure all connections are tight.

Uneven veneer thickness: Inspect the blade for wear. Adjust the CNC settings if needed.

Excessive noise or vibration: Look for loose bolts or worn gears. Lubricate moving parts.

Frequent jams: Clean out dust and wood chips. Make sure the log diameter matches the machine’s specs.

️ Pro Tip: Keep a troubleshooting checklist near your machine. Train your team to follow it step by step.

Here’s a simple troubleshooting guide:

Problem | Quick Solution | When to Call Support |

|---|---|---|

Power issues | Check cables and switches | If problem persists |

Blade dullness | Sharpen or replace blade | If blade keeps failing |

Software errors | Restart and update software | If errors repeat |

Mechanical faults | Tighten bolts, lubricate | If noise continues |

Alva Machinery offers strong after-sales support. Their team can help you with video guides, online chat, and technical advice. If you run into a tough problem, reach out for help. You save time and avoid costly downtime.

Troubleshooting keeps your machine in top shape. You get better results and fewer interruptions. With the right support and a good checklist, you stay ahead of problems and keep your business growing.

You want to make sure you pick the right veneer press for your business. Talking to industry experts can save you time and money. These professionals know the latest technology and can help you match machine capacity to your production needs. You get advice on which models work best for your wood type, job size, and workshop layout.

When you reach out to experts, ask about:

The best machine for your daily output goals.

How to optimize your workflow with the right veneer press.

Which features matter most for your team’s skill level.

How to future-proof your investment for changing market demands.

Experts can also help you avoid common problems. For example, uneven veneer surfaces often come from dull knives or too much feed pressure. You can fix this by regrinding the knife and adjusting the pressure. If you see uneven veneer thickness, check the knife position and wood moisture. These tips come from years of hands-on experience.

Tip: Many trusted brands, like Alva Machinery, offer free consultations. Their teams can guide you through choosing a press that fits your business and budget. You can find their product lineup at Alva Machinery’s product page.

Before you buy, you should test the machine in real-world conditions. Testing helps you see how the right veneer press performs with your wood type and production volume. You get a clear picture of speed, precision, and reliability.

Here’s what you should focus on during testing:

Run the machine with your actual logs to check for smooth operation.

Measure veneer thickness and surface quality after each cycle.

Watch for issues like veneer curling or uneven core diameter. These problems often come from knife gate width or wood dryness. You can solve them by adjusting the gate or spraying water on the wood.

Test the machine’s capacity by running it at full speed. Make sure it can handle your daily workload without slowing down.

Testing also lets you spot periodic variations in veneer thickness. These usually happen because of wood density changes. Adjusting knife height or replacing worn bearings can fix this. You want a machine that keeps up with your needs and delivers consistent results.

Note: Ask the manufacturer for a demo or trial period. Brands like Alva Machinery often provide hands-on testing and operator training. This helps you feel confident about your choice.

A strong service agreement keeps your right veneer press running smoothly for years. You want coverage that goes beyond basic repairs. Look for agreements that include regular maintenance, inspections, and training for your team.

Here’s a table showing what a good service agreement should cover:

Maintenance Task | Description |

|---|---|

Multiple service calls per year | Regular checkups to keep equipment in top shape |

Close inspection of all equipment | Detailed exams to catch issues early |

Tightening of screws, nuts, and bolts | Ensures all parts stay secure |

Inspection of electrical connectors | Prevents electrical problems |

Adjustment of timers, valves, heating units | Keeps performance at its best |

Inspection of motors and drive systems | Spots wear and tear before it causes trouble |

Replacement of worn or failing parts | Avoids unexpected breakdowns |

Cleaning and lubrication of critical components | Reduces friction and extends machine life |

Fine-tuning for optimal speed and efficiency | Boosts productivity and output |

Comprehensive testing for performance | Confirms machine meets your standards |

Training for operators and maintenance staff | Ensures proper handling and care |

You should also expect:

Dedicated equipment maintenance specialists.

Major powertrain and hydraulic repairs.

Repairs to hoses, seals, belts, and batteries.

Technical and visual inspections.

Oil and filter changes.

Lubrication of fittings.

A good service agreement protects your investment and helps you get the most out of your machine’s capacity. You spend less time worrying about breakdowns and more time growing your business.

️ Pro Tip: Always review the service agreement before signing. Brands like Alva Machinery offer comprehensive support and training. This keeps your right veneer press working at peak performance.

When you think about the future of your business, scalability matters. You want a veneer press that grows with you. Maybe your orders increase next year. Maybe you add new wood types or change your product line. If your veneer press cannot keep up, you lose time and money.

Start by looking at your current production. Ask yourself, “Can my veneer press handle double the workload?” If you plan to expand, you need a machine that supports higher output. Some veneer press models let you upgrade parts or add automation. You do not have to buy a whole new machine every time your business grows.

Here are some ways to check if your veneer press is scalable:

Modular Design: Some veneer press machines have parts you can swap or upgrade. You might add a faster motor or a better control system.

Software Updates: Modern veneer press models often get new software features. You can improve performance without changing hardware.

Flexible Capacity: Look for a veneer press that handles different log sizes and wood types. This gives you more options as your business changes.

Integration: If you add new machines, your veneer press should connect easily. You want smooth data sharing and workflow.

Tip: Scalability means you do not outgrow your veneer press. You save money and avoid big changes in your workshop.

Let’s compare scalable features in a table:

Feature | Why It Matters | How It Helps You Grow |

|---|---|---|

Modular Upgrades | Add new parts as needed | Boosts speed and output |

Software Flexibility | Get new features over time | Improves efficiency |

Adjustable Capacity | Handle more wood types | Expands your product range |

System Integration | Connect with other machines | Streamlines your workflow |

You want a veneer press that fits your space now and later. If you move to a bigger workshop, your machine should come with you. Some veneer press models have compact footprints but still offer high output. This helps you grow without wasting space.

Scalability also means thinking about your team. If you hire more workers, your veneer press should be easy to train on. User-friendly controls and clear displays help new staff learn fast. You do not want a machine that only one person can operate.

When you shop for a veneer press, ask about future upgrades. Brands like Alva Machinery offer machines with scalable features. You can start small and add more power or automation as your business grows. Check out their product lineup at Alva Machinery’s product page to see which veneer press models fit your growth plans.

Note: A scalable veneer press protects your investment. You do not need to replace your machine every time you expand. You stay flexible and ready for new opportunities.

Scalability keeps your business moving forward. You get more value from your veneer press and stay ahead of the competition. Plan for growth now, and your veneer press will support you every step of the way.

Choosing the right gear pressing veneer peeling machine starts with clear requirements. You want to match panel size, press type, and features to your daily output. Align your machine’s capabilities with your business goals for long-term success.

Test machines before you buy.

Talk to experts and review support options.

Look for scalable solutions from trusted brands like Alva Machinery.

Ready to take the next step? Make a confident choice and set your business up for growth.

You should look at your production needs, wood type, and press types. Think about large diameter wood, output volume, and your budget and support options. These key factors help you pick the best press for your workshop.

Gear pressing and hydraulic press types handle large diameter wood well. You get steady pressure and smooth veneer sheets. If you process high volume production, these press types keep your workflow fast and reliable.

Pick a press with strong motors and fast peeling speed. Multi-daylight press types and gear pressing models work great for high volume production. You save time and get more veneer sheets every day.

Yes, many gear pressing press types work with hardwoods and softwoods. If you process large diameter wood, choose a press with adjustable settings. This lets you switch between wood types without slowing down.

Look at the total cost, warranty, and after-sales service. Brands like Alva Machinery offer strong budget and support options. You get installation help, technical support, and easy access to spare parts.

Clean your press daily, check for loose bolts, and lubricate moving parts. Sharpen blades often. Follow the manufacturer’s guide. Regular care keeps your press running smoothly and extends its life.

You can visit Alva Machinery’s product page. They offer gear pressing, hydraulic, and multi-daylight press types for different needs. You get strong support and quality machines for your business.

Check the press settings and blade sharpness. Make sure your press type matches the log size. If problems continue, contact your supplier for advice or upgrade to a model designed for large diameter wood.